Desired Relative Humidity (RH) as the Basis for all Applications

Relative Humidity is the amount of moisture in air expressed as a percentage of how much moisture is in the air relative to how much total moisture the air will hold at a given temperature. 45-50% RH is considered air moisture equilibrium for most materials. Practically, many projects target 35-45% RH.

The important issues regarding relative humidity in dry air and low humidity manufacturing environments (less than 30% RH) center on the following quality control concerns:

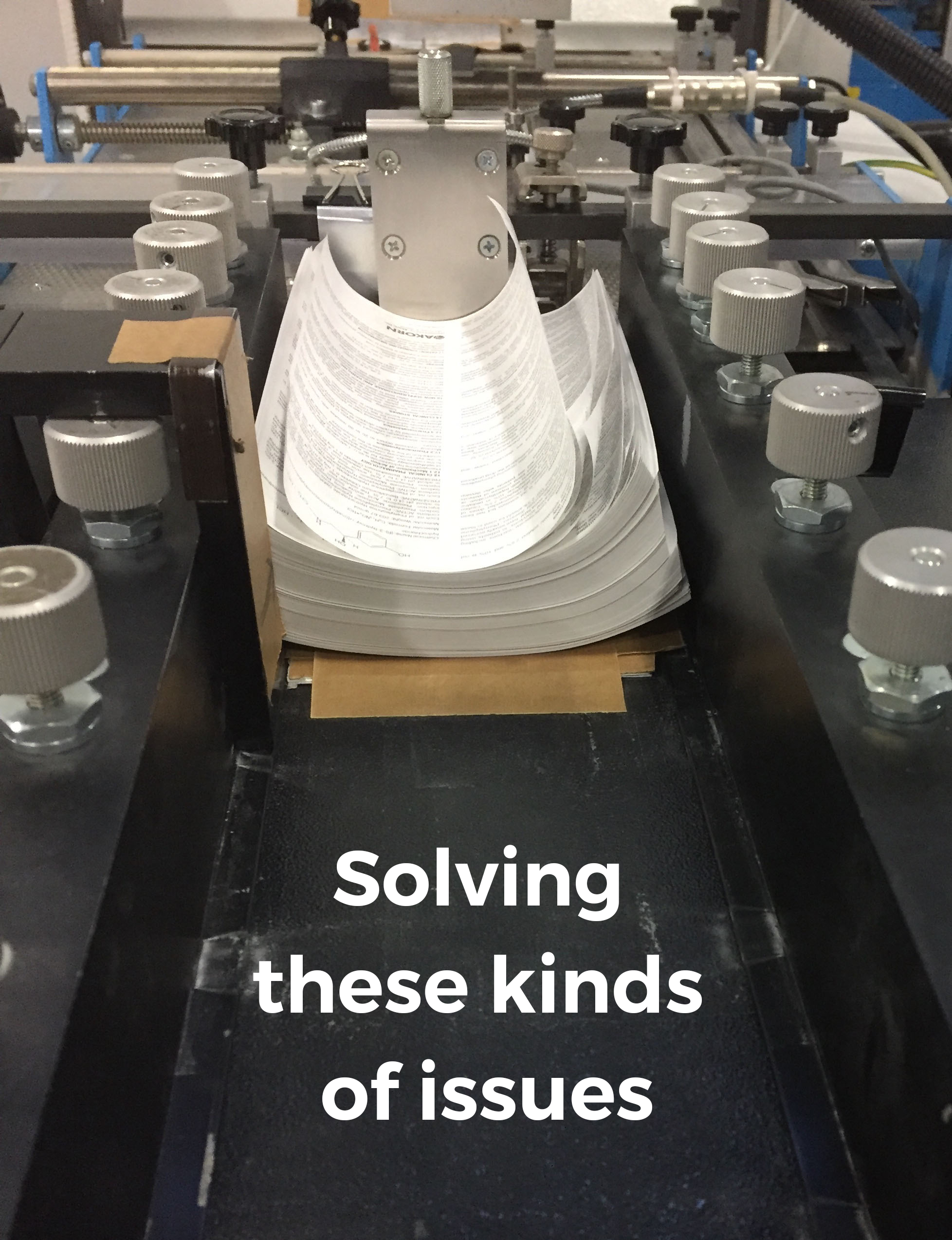

- Hygroscopic sensitive materials (take on or give off moisture) such as wood, paper and organic textiles demonstrate very unstable characteristics such as dimensional and shape variations.

- Electro-static-discharge (ESD) buildup of charges on machinery, materials and people effect lower quality output of material production processes.

FanMist for Your Application

The recommended FanMist equipment package for your facility is based on “psychrometric building data” for load calculations (total moisture required) knowing your plant data as follows:

- Dimensions of area(s) to be humidified and their ceiling height.

- Total CFM’s of exhaust air and/or makeup air (whichever is greatest).

- Your desired RH at your average indoor air temperature during winter operations; e.g. 45% RH @ 72˚F.

The final FanMist equipment package recommendation includes our suggested layout for all equipment placement. Additionally, we provide installation guidance, a FanMist User Manual and guidance on water treatment.

Review Industry Standards for Relative Humidity: Woodworking • Paper/Print/Labels • Electronics • Textiles

Woodworking • Cabinetry

Maintain

35-50% RH

Preserving Equilibrium Moisture Content (EMC) – protecting against warping, bowing, cupping, shrinkage, checking & glue joint failures.

Paper • Print • Label

Maintain

40-60% RH.

Preserving hygroscopic stability – preventing variations in paper dimensions, weight and ink drying, equipment miss-feeds, & static electricity (ESD).

Electronics

Maintain

40-60% RH

Maintaining required relative humidity standards for electronics production and processes – preventing the unintended “built in” latent effects caused by static electricity.

Textiles

Maintain

40-60% RH

Preserving the manufactured integrity of fibers against the affects of static electricity, brittleness – and decreasing suspended air dust as by-product of fiber process operations.

Summary Descriptions of Installed FanMist Systems

Type of Application

Project Requirements

Load Calcs / Moisture Required

FanMist Equipment Installed

Woodworking – Rough Mill, Assembly & Storage

36″ FanMist Installed 2013

Water Treatment: Reverse Osmosis (RO)

Maintain: 35% RH @ 75˚ F (Avg)

Area: 668,000 ft2 x 22′ Ceiling

Makeup Air: 200,000 CFM

Load Calculations based on 200K CFM

Requires 4447 lbs/hr (8.89 gpm)

5 each 2 gpm 1 zone pump stations;

40 each 36″ Fans @ 96 lbs/hr/fan = 3840 lbs/hr (10 gpm); Max Pump Output: 5000 lbs/hr (7.68 gpm)

Woodworking – Rough Mill, Assembly & Storage

36″ FanMist Installed 2015

Water Treatment: Reverse Osmosis (RO)

Maintain: 35% RH @ 70˚ F

Area: 128,640 ft2 x 28′ Ceiling

Makeup Air: 117,156 CFM

Load Calculations based on 117,156 CFM

Requires 2847 lbs/hr (5.69 gpm)

4 each 2 gpm 1 zone pump stations;

26 each 36″ Fans @ 96 lbs/hr/fan = 2496 lbs/hr (4.99 gpm); Max Pump Output: 4000 lbs/hr (8 gpm)

Woodworking – “Spot” humidification within 100K f2 plant

30″ FanMist Installed 2012

Water Treatment: Water Softening

Maintain: 45% RH @ 65˚ F

Area: 5000 ft2 x 30′ Ceiling

Air Exchanges/Hr: 4

Load Calculations based on 150K ft3 @ 4 airx’s/hr

Requires 264 lbs/hr (.53 gpm)

1 each 1 gpm 1 zone pump stations;

3 each 30″ Fans @ 96 lbs/hr/fan = 288 lbs/hr (.576 gpm); Max Pump Output: 500 lbs/hr (1 gpm)

Print & Label Production

30″ FanMist Installed 2011

Water Treatment: DIBS (Deionized Blending System)

Maintain: 45% RH @ 72˚ F

Area: 57,600 ft2 x 21′ Ceiling

Makeup Air: 26,000 CFM

Load Calculations based on 26,000 CFM

Requires 813 lbs/hr (1.63 gpm)

1 each 2 gpm 1 zone pump stations;

8 each 30″ Fans @ 96 lbs/hr/fan = 768 lbs/hr (1.54 gpm); Max Pump Output: 1000 lbs/hr (2 gpm)

Print & Label Production

30″ FanMist Installed 2015

Water Treatment: DIBS (Deionized Blending System)

Maintain: 45% RH @ 72˚ F

Area: 44,370 ft2 x 21′ Ceiling

Makeup Air: 10,000 CFM

Load Calculations based on 10,000 CFM

Requires 392 lbs/hr (.78 gpm)

1 each 1.5 gpm 1 zone pump stations;

4 each 30″ Fans @ 96 lbs/hr/fan = 384 lbs/hr (.77 gpm); Max Pump Output: 750 lbs/hr (1.5 gpm)

Print & Label Production

36″ FanMist Installed 2016

Water Treatment: DIBS (Deionized Blending System)

Maintain: 40% RH @ 70˚ F

Area: 120,000 ft2 x 30′ Ceiling

Exhaust Air: 45,234 CFM

Load Calculations based on 45,234 CFM

Requires 1546 lbs/hr (3.09 gpm)

1 each 3.1 gpm 2 zone pump stations;

10 each 36″ Fans @ 144 lbs/hr/fan = 1444 lbs/hr (2.88 gpm); Max Pump Output: 1550 lbs/hr (3.1 gpm)

Electronic Assemblies Manufacturing

18″ & 24″ FanMist Installed 2013

Water Treatment: DIBS (Deionized Blending System)

Maintain: 40% RH @ 72˚ F

Area: 45,000 ft2 x 12-17′ Ceiling

Air Exchange Rate: 1.5-2.0 airx’s/hr

Load Calculations based on 675K ft3 @ 1.75 airx’s/hr (avg)

Requires 384 lbs/hr (.79 gpm)

1 each 1.5 gpm 1 zone pump stations (re-pulleyed to 1 gpm);

4 ea 18″ fans @ 24 lbs/hr/fan; 8 ea 24″ fans @ 48 lbs/hr = 264 lbs/hr (.528 gpm)

Textiles (Medical)

24″ FanMist Installed 2014

Water Treatment: Water Softening

Maintain: 40% RH @ 72˚ F

Area: 18,480 ft2 x 20′ Ceiling

Air Exchange Rate: 1.2 airx’s/hr

Load Calculations based on 369,600K ft3 @ 1.2 airx’s/hr

Requires 218 lbs/hr (.44 gpm)

1 each 0.5 gpm 1 zone pump station;

3 each 24″ fans @ 64 lbs/hr = 192 lbs/hr (.384 gpm)